I. Introduction

Welcome to our blog post on designing custom patterns for perforated wood acoustic panel! In this article, we will dive deep into the world of wooden acoustic panels and understand their design by understanding their significance in terms of both aesthetic appeal and acoustic performance. With proper understanding, custom patterns can help transform spaces from boring to lively in no time at all!

Wood perforated panel is not only functional but also visually appealing. Their natural and warm aesthetic blend seamlessly into many interior design styles. But by customizing patterns onto these panels, you can elevate their visual impact and create a truly customized environment.

II. Understanding Perforated Wood Panels

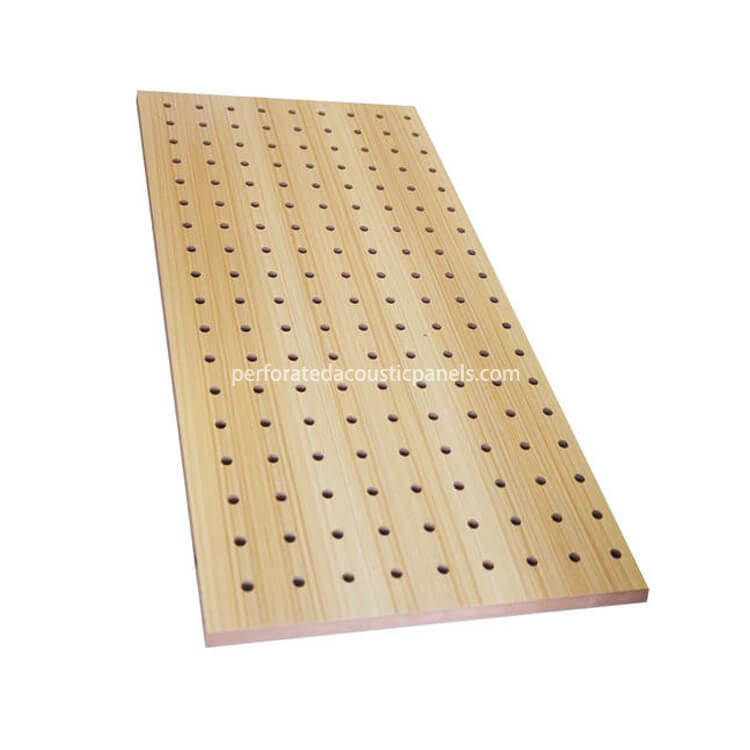

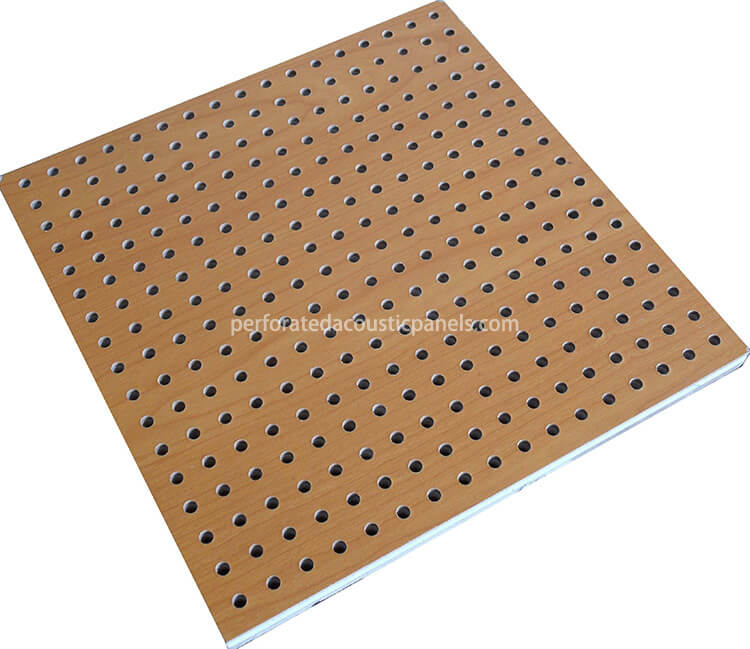

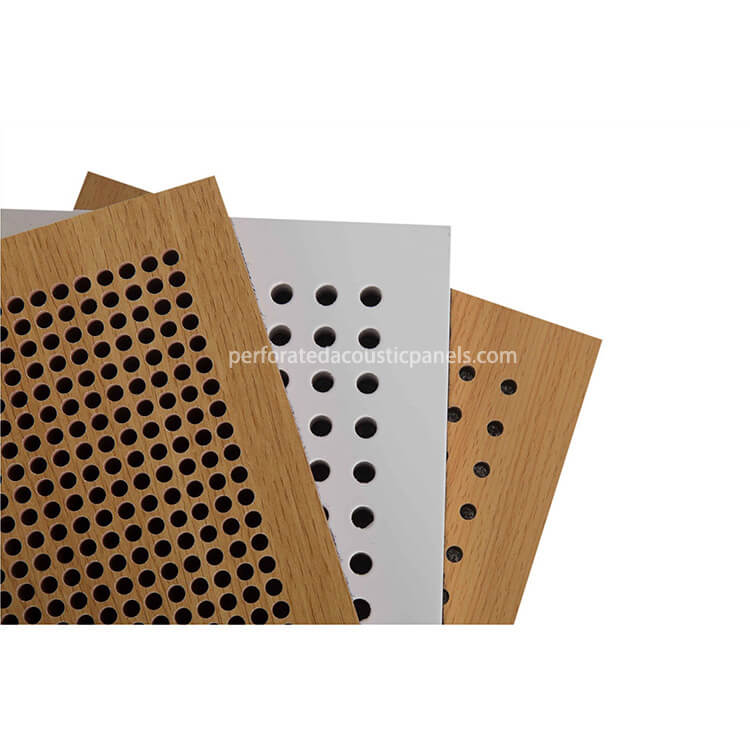

Perforated wood panels are specially-designed panels featuring small holes or perforations strategically arranged to absorb and control sound waves, providing effective noise absorption and balance in spaces where noise reduction and balance is key. Their acoustic properties make these panels the ideal solution.

Acoustic perforated wooden panel can be created using various types of wood, each offering their own distinct properties. Common examples include oak, maple, birch and walnut; each offering unique grain patterns, colors and textures that enable you to find one that meets your design preferences.

Perforated wood panels’ acoustic properties depend on factors like hole size, pattern density and panel thickness. When sound waves pass through perforations they encounter resistance that causes energy loss thus reducing noise levels in their surrounding environment – an effect known as sound absorption that makes perforated panels an excellent way to improve acoustic performance in spaces such as offices, auditoriums, recording studios or home theaters.

Stay tuned for next part of this blog post where we will explore the process of designing custom patterns for perforated wood acoustic panel, including what factors must be taken into account and techniques involved in creating stunning and visually striking patterns.

III. Designing Custom Patterns

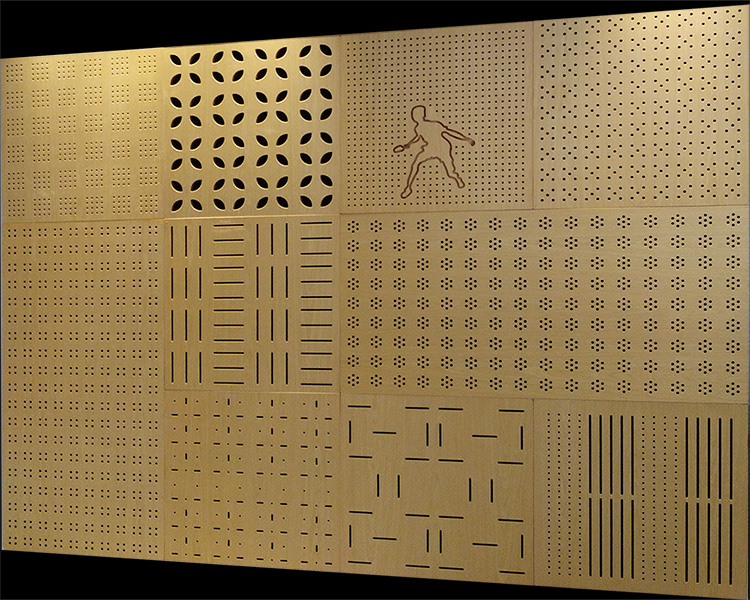

Custom patterns play an essential role in elevating the aesthetics of perforated wooden acoustic panel, by providing visually captivating elements to elevate the ambiance and elevate overall ambiance. By adding intricate geometric designs, organic motifs or abstract designs – custom patterns allow for personalization and creativity when customizing perforated wood panels for use in spaces like your own.

Custom patterns offer many advantages for wood panel perforated, such as versatility. Unlike pre-designed patterns, which cannot be tailored to different spaces and themes, custom patterns are tailored specifically to meet the design requirements for every space – be it residential, commercial, or public venue. Furthermore, custom patterns create harmonious environments by harmonizing perforated panels with other interior elements to form one aesthetically pleasing atmosphere.

IV. Factors to Keep in Mind when Designing Custom Patterns

Designing custom patterns for perforated wood ceiling and perforated wood wall panel requires taking both aesthetic and acoustic considerations into account. While visual impact should certainly not be overlooked, its performance must also meet or surpass expectation.

Pattern density and hole size are both key elements in pattern design. Pattern density refers to the number of perforations per unit area; an increase can improve sound absorption capabilities due to more surface area available for sound waves to travel across. Furthermore, hole size affects panel’s acoustic performance with smaller holes providing superior sound absorption at higher frequencies.

Spacing and arrangement of perforations also play a pivotal role in producing desired acoustic results. The distance between holes affects how effectively they absorb sound at different frequencies; additionally, their arrangement impacts diffusion of sound waves, contributing to a more balanced acoustic environment.

By carefully considering these factors and consulting acoustic experts and designers, custom patterns can be designed that not only add visual appeal to perforated wood panels but also maximize their acoustic performance. We will discuss techniques involved in crafting such patterns as well as various uses of ceiling perforated in interior design applications in next part of this blog post.

V. Create Your Own Custom Patterns Techniques

Custom wood panels require special techniques that enable precision and variety in design. There are various ways that can help bring your creative pattern ideas to life.

1. Laser Cutting

Laser cutting is an efficient method used to craft intricate wood panel patterns with pinpoint accuracy. A laser beam is directed at the panel surface, vaporizing or burning away wood fibers to form designs in just minutes – perfect for intricate patterns with complex detailing! This technique offers unparalleled accuracy.

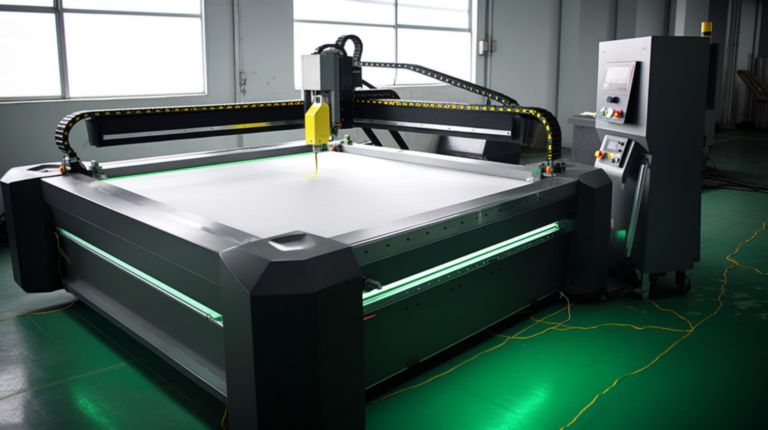

2. CNC Routing

CNC (Computer Numerical Control) routing involves using computer-controlled machines to carve patterns on wood panels using computer programs that follow predefined paths to remove pieces of wood to achieve the desired design. CNC routing offers flexibility in design while simultaneously replicating patterns precisely, making it an effective technique for perforated wood panels with custom patterns.

3. Additional Methods

Beyond laser cutting and CNC routing, other methods like water jet cutting and hand carving offer unique opportunities for creating custom patterns on wood panels. Each of these can be tailored specifically to suit specific design specifications.

These methods offer precision and versatility that enable the creation of complex yet visually stunning custom patterns on acoustic perforated board ceiling, from geometric shapes and nature-inspired motifs to abstract designs – adding sophistication and sophistication to your space.

VI. Applications of Perforated Wood Panels

Acoustic perforated wood panels have many applications in interior design, providing both aesthetic and practical benefits. Let’s examine some of their most frequent applications here:

Wall Panels

Perforated wood wall can add texture, depth, and visual interest to any space by being installed as decorative wall panels. These decorative pieces can be utilized in offices, hotels, restaurants and residential interiors alike to create a distinctive focal point or enhance overall ambiance.

Ceilings

Installing perforated ceiling systems not only adds an aesthetic element but can also contribute to improved acoustics by effectively absorbing sound waves and decreasing echo, creating a more pleasant and comfortable atmosphere.

Architectural Elements

Wood perforated panels can be integrated into architectural elements like room dividers, partitions, and screens to add visual interest and create the right balance between openness and privacy while adding a beautiful aesthetic element to overall designs.

Perforated wood panels present designers and architects with endless design possibilities. Used alone or combined with other materials, they can produce striking visual effects that contribute to an unforgettable interior design. Perforated panels can also be tailored to any desired aesthetic – contemporary to traditional settings alike can use perforated panels with ease! Its versatility also makes perforated wood panels an attractive option.

VII. Maintenance and Care Tips

Proper care and maintenance of perforated wood ceiling tiles is key to their long-term performance and optimal lifespan, so here are a few guidelines to keep them looking their best:

1. Regular Cleaning

Dust and dirt can accumulate over time on the panels’ surfaces. To effectively cleanse them, use a soft lint-free cloth or gentle brush with no bristles. Any harsh materials or harsh chemicals could potentially harm either the wood or its finish and must be avoided at all costs.

2. Mild Cleaning Agents

For more stubborn stains or dirt build-up, a mild detergent mixed with water may work wonders. Apply it with a soft cloth, applying liberally over affected areas until they have been completely wiped down with this solution. Rinse panels thoroughly afterward before drying them completely to avoid moisture damage.

3. Avoid Excessive Moisture

Wood panels can become vulnerable to moisture damage over time, so it is vitally important that they don’t come into direct contact with excessive water or humidity levels. Clean up any spills immediately and maintain an environment with adequate ventilation in order to minimize moisture build-up.

4. Regular Inspections and Repairs

Periodically check panels for signs of damage such as cracks, warping or loose perforations. Immediately address any issues to prevent further deterioration and maintain integrity of panels; seek professional assistance if extensive repairs are required.

By following these maintenance and care guidelines, you can ensure your sound absorption perforated wood panels remain in great condition for years to come – providing both aesthetic appeal and acoustic functionality.

Perforated Acoustic Wood Panels

Acoustic Perforated Wall Manufacturers Acoustic Perforated Wood Panels Acoustic Perforated Wall Suppliers

Wooden Acoustic Ceiling Panels

Perforated Ceiling Panels Suppliers Wooden Acoustical Ceiling Panel Acoustic Wood Ceiling Tiles

VIII. Conclusion

Custom-patterned sound absorbing perforated wood acoustic panels provide multiple benefits to interior spaces. By adding customized patterns, you can enhance aesthetics, personalize environments and boost acoustic performance of these spaces.

Custom patterns were explored as an effective means of increasing the visual appeal of perforated wood panels and explored their flexibility when applied to specific spaces and themes. Factors like pattern density, hole size, spacing, and arrangement were emphasized as essential considerations in reaching desired acoustic results.

Laser cutting and CNC routing offer precise design features with their versatile capabilities for creating custom patterns, as do perforated MDF panels for interior design purposes such as wall panels, ceilings, or architectural elements. We discussed both techniques as well as their various applications such as wall panels, ceilings and architectural features.

To extend the longevity of your perforated woods, we offered maintenance and care tips that emphasize regular cleaning with mild cleaning agents as well as periodic checks for repairs.

By adding custom patterns to groove wood panel or perforated wood veneer panels, you can create an environment with truly distinctive style while enjoying improved acoustics. We urge you to explore all the ways these panels could transform your projects and unleash your creative spirit – turning ordinary spaces into unforgettable experiences!

Be creative when it comes to designing custom patterns for perforated wood acoustic panels – the options are truly limitless! Let your imagination soar and create spaces that are both visually arresting and acoustically pleasing.

Perforated Sound Absorption Panels

Perforated Acoustic Panels China Wooden Sound Absorption Panel Perforated Acoustic Panels Price